The Pump Lamp

When I entered seventh or eighth grade—1959 or maybe 1960—I was assigned to Shop class, as all the boys were. The girls went to Home Ec, even though a few of them would have preferred Shop. (Some boys probably would have traded places, too, but none of us would have admitted it.)

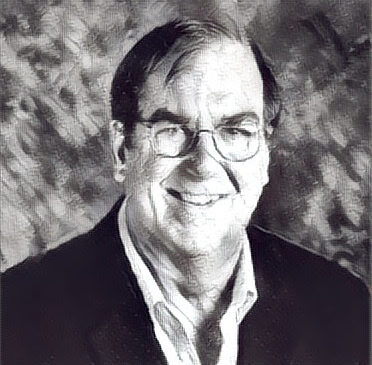

Shop came with a menu of projects: bookshelves, magazine racks, cutting boards. I drew the assignment to make a “pump lamp”—a wooden replica of an old hand-water pump with a working light bulb at the top. Here’s what it looked like when finished:

It began with the base: a rough, not-quite-square block of wood. The first lesson was how to true it up — using a T-square to measure, cut, sand, and then drill a perfectly straight channel for the lamp cord, only a few inches deep. If the drill drifted even slightly, it would burst through the side and ruin the whole piece.

The upright “pump housing” started the same way: another block to square, level, and sand until it stood perfectly plumb. Into that, we had to carve the opening where the handle would pivot and a hole in the center for the wire.

The little cylindrical “barrel” on the side was our first attempt at using the lathe. The teacher cut the center part for us, but we shaped the outer curves and the decorative rings meant to look like old steel bands.

The copper work was its own adventure. We cut a strip of soft copper for the bracket that attached the handle to the pump housing. We create the notch for the handle’s axle. None of this came pre-fit—every alignment had to be exact or the handle wouldn’t move freely.

The teacher probably used the band saw to cut the handle blank, but everything else was on us: drilling the axle holes, sanding the curves, fitting the chain, assembling the whole pivot mechanism so it actually worked.

Many attempts were sacrificed to mistakes, but that was part of the point. We learned the gospel of Shop: safety first; measure twice, cut once; keep everything square, level and plumb; think; plan ahead.

The electrical work was the final challenge. We mounted a bare-bulb socket to a metal plate at the top of the pump housing, drilled the plate ourselves, and then threaded the wire up through the narrow interior cavity without mangling it. For a 12-year-old, this was serious problem solving.

Once assembled, everything got a final sanding and a stain or shellac that made it gleam. When I gave it to my mother, she was delighted. For years, that pump lamp sat on my nightstand. I didn’t take it to college, but it’s never left my memory.

* * * * * * *

A few years later, after retiring from the Navy, my father took a part-time job teaching Shop in the Madison school system. After a career training more than 10,000 Navy pilots, he quickly concluded that “straightening out nineteen-year-olds isn’t much different from straightening out fourteen-year-olds.” He quit when the district insisted he go to Montclair State for a teaching certificate—bureaucracy he had no patience for.

I sometimes wonder what happened to Shop classes. They gave us confidence, dexterity, and a sense of how things actually fit together. The next year, I took another vocational elective called Mechanical Drawing, which taught me geometry, perspective, and how to think in three dimensions—skills as valuable as anything else I learned in school—and a lot of fun.

Those classes shaped me far more than I realized at the time.